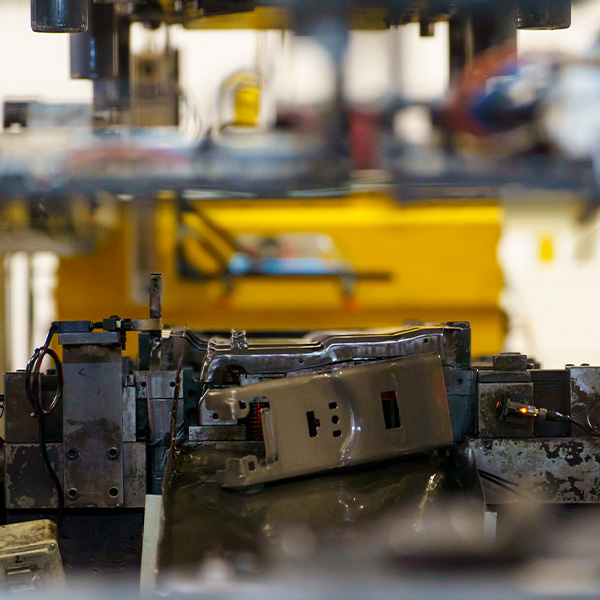

Metal stamping is a production process that allows us to obtain complex-shaped metal parts. Teknia has production capacities in Europe and America to support its customers’ stamping needs. The Group manufactures different types of components thanks to its wide range of tonnages in its presses.

Teknia is an expert in stamping small and medium-sized metal components for different types of assemblies, which are then put together into highly complex products. At Teknia, stamped products are manufactured to be assembled into seats, safety, and body and chassis components. By combining stamping with other technologies available in the Group, Teknia offers high value-added products, and is present in the different areas of a vehicle.

Global Stamping Capacities to Support Customers

Teknia has a wide variety of presses ranging from 250 to 1000 tons, covering the needs of its customers and offering maximum versatility in the manufacture of stamping parts. Furthermore, Teknia is able to offer additional welding and assembly solutions for its stamped metal components.

Teknia has global stamping capabilities, which enables the company to support customers in many different geographies, both in Europe and the United States. This also allows Teknia to offer its customers tailor-made stamping solutions.

For any questions, send us an email

Get to know our products