Teknia uses high-performance automated lines for the manufacture of machined components. The aim is to maintain the highest level of quality, recognised by our customers with several awards, while maintaining the competitiveness required by such a demanding sector as the automotive industry.

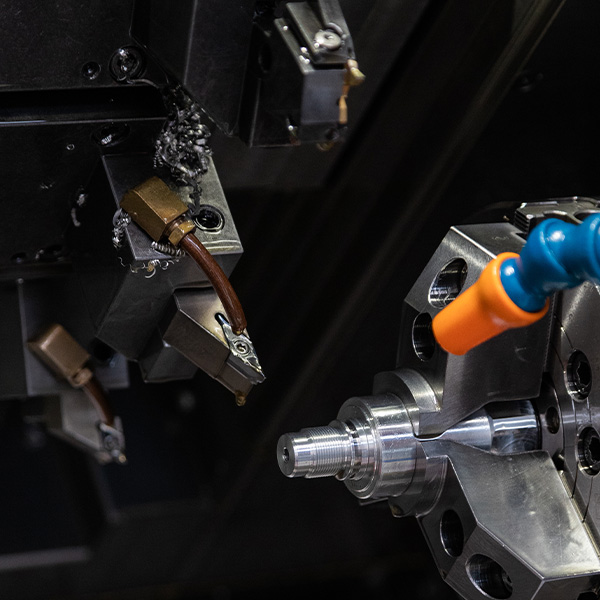

Teknia manufactures highly complex machined components with a wide variety of diameters, ranging from 5 mm to 66 mm. The Group’s capabilities in this technology include the use of various materials in machining processes, such as steel, aluminium, and brass. Teknia uses high-performance automated lines for the manufacture of machined components.

Different Machining Processes for a Diversified Portfolio

Teknia supports its customers with many types of machining processes within the mobility sector. The components the Group manufactures are suitable for any type of vehicle. For example, Teknia parts are integrated into multiple sensor and chassis parts, as well as electrical and braking systems.

The Group has extensive experience in the manufacture of brake pistons, a key part for the safety area. In addition, the company specialises in shafts, a strategic product with great growth potential. Teknia is currently working on different machining products for electrification.

For any questions, send us an email

Get to know our products