It is worth highlighting that, alongside sustainability, safety represents a fundamental pillar of vehicles both today and in the new mobility era. For this reason, the safety components category is the largest within the Group and constitutes a strategic segment for the company in terms of sales and continuous growth.

Safety, the top priority in the automotive sector

The safety category is Teknia’s most strategic product family and includes structural and functional components designed to ensure passenger protection in different scenarios. This is because safety has been a fundamental aspect of all vehicles for decades and will continue to be as we move toward new mobility.

The safety product category encompasses passive safety elements, such as airbag or seat belt components, as well as numerous systems required for a vehicle to decelerate or stop quickly. All these components, therefore, help prevent a collision and protect occupants in the event one occurs.

Thanks to its broad technological offering, Teknia has extensive experience in manufacturing specialized safety components for automobiles. The innovation, precision, and quality of the materials used by the Group allow it to meet customers’ needs by developing products that enable driving with maximum safety.

In addition, the specialized R&D centers in Poland and Spain address customers’ complex needs, from design to mass production, through complete vertical integration, including the in-house design and manufacturing of all tools, welding lines, and test equipment. Teknia has strong engineering capabilities and a global presence in the safety product category, particularly in brake reservoirs and painted airbag covers.

Brake systems

Brake systems are a key element for the overall safety of a vehicle. Without them, a car cannot slow down or stop. Teknia is mainly an expert in manufacturing components such as:

- The brake fluid reservoir, which contains the brake fluid used in the hydraulic braking system.

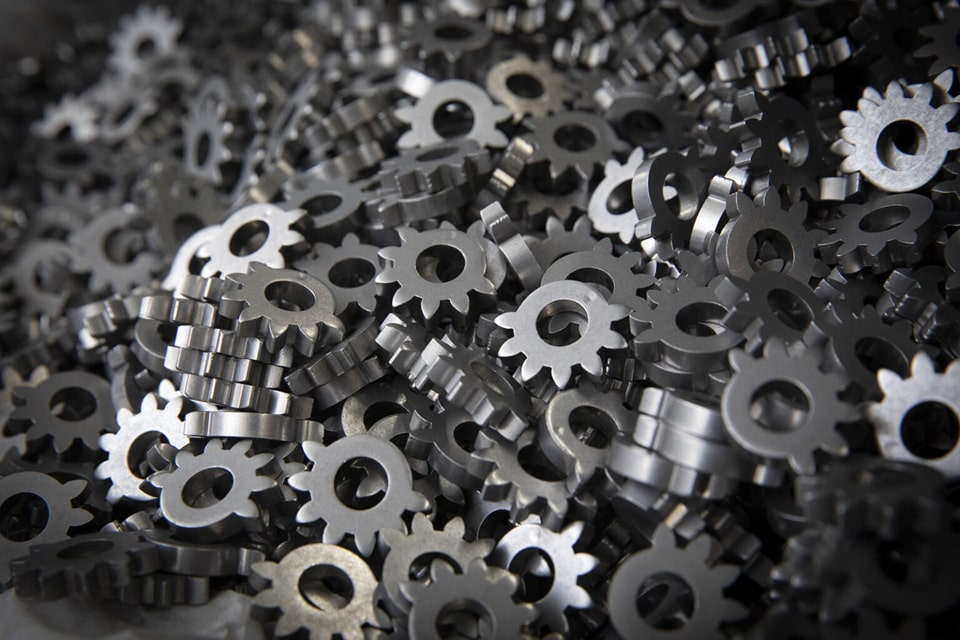

- Brake pistons. The Group manufactures 25 million brake pistons per year, equivalent to 6 out of every 10 vehicles produced in Europe having a Teknia brake piston.

Airbag systems

Airbag systems are part of the vehicle’s passive safety and are essential for protecting occupants during an accident. Teknia specializes in manufacturing multiple airbag components, with key products such as:

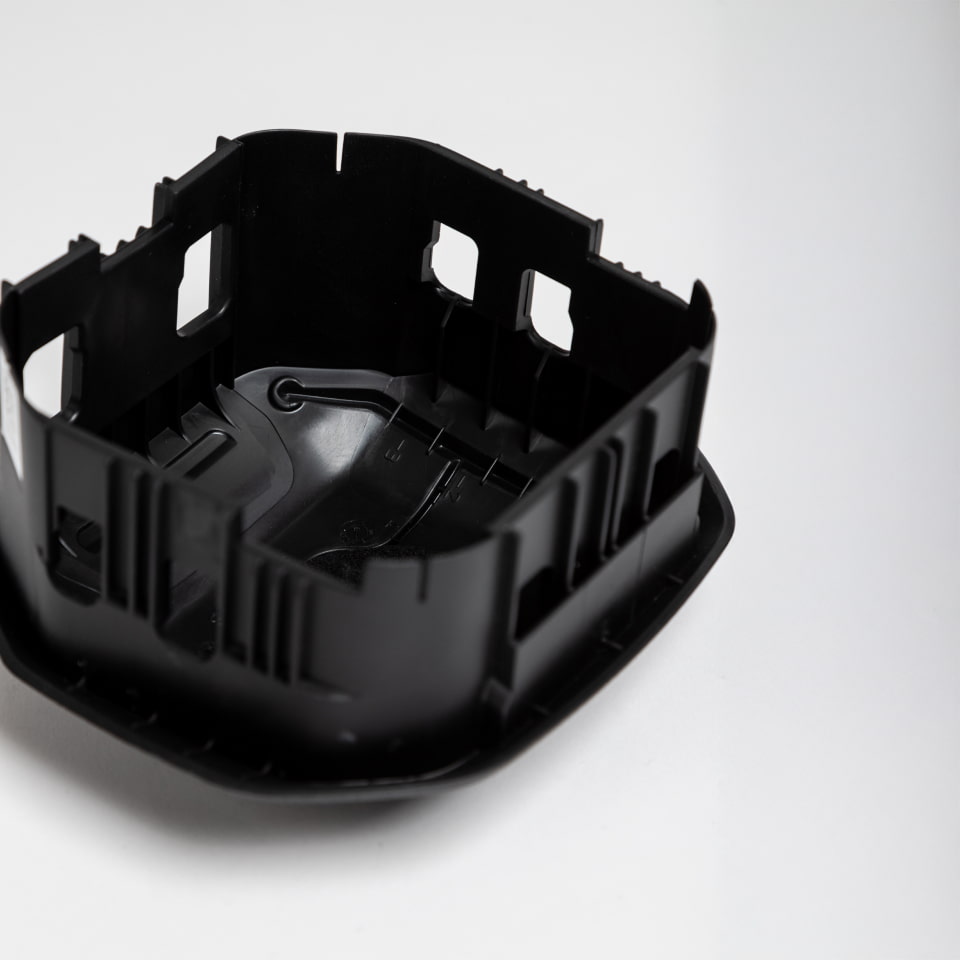

- The airbag housing (the box in which it is stored).

- The airbag cover.

- The horn plate, a mechanism that enables the horn to function and must be coordinated with the steering wheel airbag.

Seat belt

The seat belt is one of the most important advancements ever seen in the automotive industry to protect vehicle occupants. Teknia specializes in developing seat belt pretensioners, active safety devices that, in the event of a collision, rapidly tighten the belt webbing to keep the occupant firmly secured to the seat.

A product category that includes all Teknia’s technologies

The safety category is represented across the Group’s four technologies:

- Inyección de plástico

This technology is essential for offering customers innovative mobility manufacturing solutions in interiors, electronics, and, of course, safety. Specifically, Teknia’s plastic injection plants develop painted airbag covers and brake fluid reservoirs. - Metal

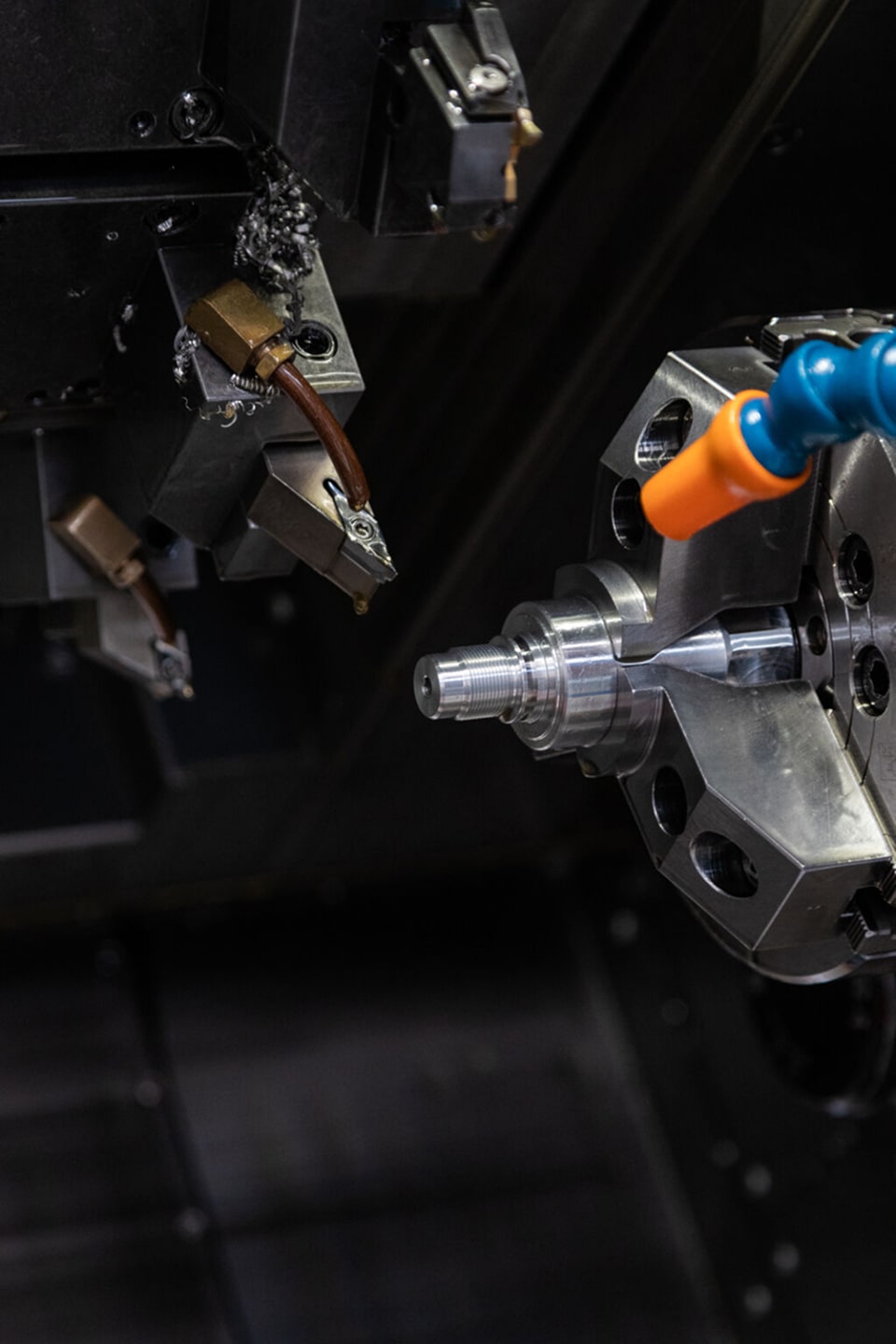

Metal is a key technology in the manufacture of high-precision metal components for the automotive industry. Teknia, as a multi-technology supplier with extensive experience in tube forming and metal stamping, integrates both areas of expertise under this technology to offer complete and efficient solutions to its customers. Its technical and production capacity makes the Group a trusted partner for the leading OEMs and TIER-1 companies in the sector. - Mecanizado

This production technique allows Teknia to give specific shapes and features to metal components, such as cylindrical parts, actuators, shafts, and other symmetrical forms. Using this technology, the Group manufactures, among other components, brake pistons. - High Pressure Die Casting (HPDC) is a technology that allows metal components with the necessary properties and finish to be obtained by transforming aluminium and magnesium from their liquid state to their final solid form, using internally developed tools. Its high precision and repeatability make it a key technique for ensuring the structural reliability and safe performance of essential parts in vehicle systems.

This production technique allows Teknia to give specific shapes and features to metal components by transforming aluminum and magnesium from a liquid to a solid state using in-house designed and manufactured tooling. Using this technology, the Group manufactures a wide variety of components for the braking system, including those for the brake pump.

Safer and more sustainable vehicles

The vehicles of tomorrow will be safer, but also more sustainable. Since its origins, sustainability has been integrated into Teknia’s business strategy and is part of the daily work of its people and operations. The objective is to become the best multi-technology partner for customers in manufacturing a more efficient, safe, and environmentally friendly mobility.

Teknia’s efforts are focused on creating components for sustainable mobility, leaving a positive impact on people and the environment. The goal is to achieve climate neutrality across all Group operations and to provide customers with products that are completely carbon-neutral. As part of this commitment, Teknia is continuously improving the efficiency of all its processes.

In its efforts to reduce its environmental footprint and promote responsible practices throughout the supply and production chain, Teknia has developed in recent years several initiatives to encourage energy savings and circular economy practices at its production plants. Notable measures include the installation of variable speed drives in equipment to reduce energy consumption, as well as the use of recycled materials that minimize environmental impact without compromising quality.

Likewise, the Group is committed to using photovoltaic self-consumption facilities and adopting renewable energy in all its factories. Thanks to the set of improvements implemented, the company’s emissions intensity has been reduced by more than 13%. Ultimately, Teknia is able to offer its customers safer, more innovative, and more sustainable solutions. More information is available in the Sustainability Report.

Teknia’s multi-technology offering, highly qualified human capital, competitive production processes, and advanced capabilities for manufacturing automotive components enable the Group to meet its customers’ specific safety needs globally, combining innovation, efficiency, quality, and social and environmental responsibility.

Plants specialised in safety

Uherský Brod

Rzeszów

Azuqueca

Barcelona

Elorrio

Manresa

For any questions, send us an email

Get to know our technologies