The powertrain products manufactured by the company focus primarily on four areas: engine components, air conditioning system components, cooling and fuel systems, and starter motors and battery systems.

Teknia is ready for the future

Teknia’s powertrain product category encompasses multiple components designed to help control the temperature both inside the engine compartment and in the vehicle itself. Essentially, they contribute to the proper functioning of the car while improving the overall comfort of the end user travelling on board.

It is no secret that we will see significant changes in the automotive industry over the coming years. Electric vehicles will become increasingly important and their market share will continue to grow. However, it should be noted that the demand for air conditioning will remain, as all vehicles will continue to need this function in the future.

The reality is that electrification is creating even more opportunities for Teknia’s products in this category. Electric powertrains require much more complex and efficient heat management for batteries and electronic components such as control units or inverters than traditional vehicles. In addition, the cooling requirements for electric vehicles also require tanks to store and distribute coolant and various tubular components to convey the coolant through the cooling circuit.

In short, the Group is ready to provide its manufacturing solutions to customers around the world as a multi-technology partner. Teknia’s technical knowledge and accumulated experience enable it to offer innovative manufacturing methods, ranging from new products to complete co-development with customers through its advanced manufacturing department. All this with the aim of shaping the mobility of tomorrow.

A clear competitive advantage in the sector

If there is one thing that characterises the Teknia Group, it is its strategy focused on quality and efficiency, as well as the application of multiple technologies that the company is able to combine to manufacture more complex end products. Examples of this within this category include:

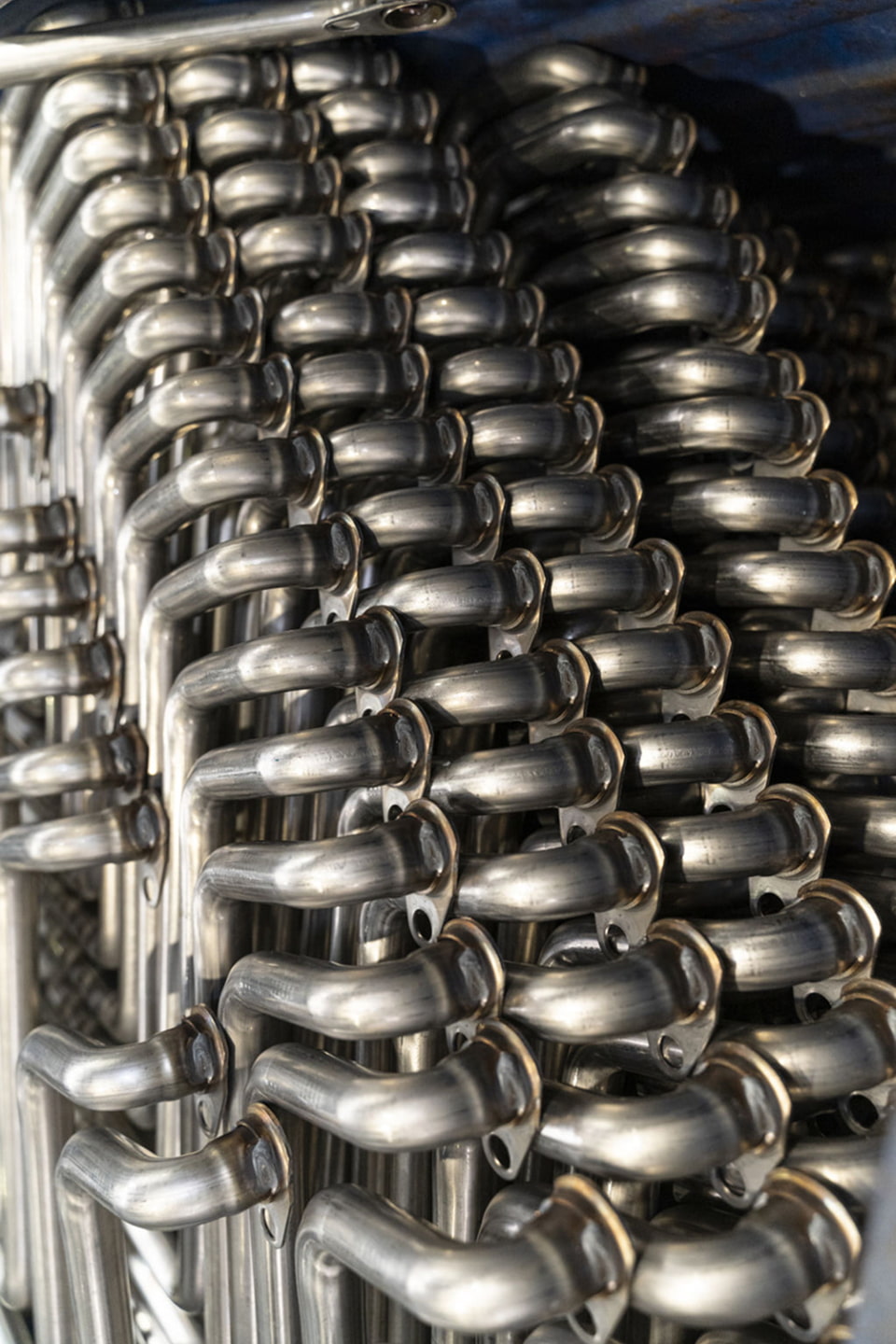

- Fuel filler pipes: pipe forming + stamping + welding/assembly and testing.

- Oil level dipsticks: plastic injection, overmoulding + stamping + assembly and testing.

- Cooling tanks (injection moulding + welding + pad printing + assembly and testing of all components manufactured in-house).

In addition, Teknia has made significant internal technological advances. In the case of tanks, the Group integrates global capabilities and vertical integration production, backed by an D&D Centre where specific tools are designed and manufactured.

Furthermore, the in-house D&D for producing shaped tube lines allows the company to manufacture parts in less than 4 seconds with the highest quality. Ultimately, Teknia has its own design and construction of tube production lines and welding solution capabilities.

Advanced technologies for powertrain product development

Teknia has a long history of manufacturing parts used in various vehicle engine and air conditioning applications. In fact, these components were some of the Group’s first manufacturing projects.

Currently, the powertrain product category is represented in all Teknia technologies, with products ranging from camshaft end pieces, silencers, starter motor housings and engine mounts to fuel/coolant pipes, rotor/armature shafts and expansion tanks.

- Plastic injection

This technology is essential for offering customers innovative mobility manufacturing solutions in terms of safety, interiors and electronics. Teknia has the highest level of expertise in plastic injection of cooling tanks. This is a key product, as each car requires at least one unit per vehicle. With electrification, this number could even increase significantly. - Metal

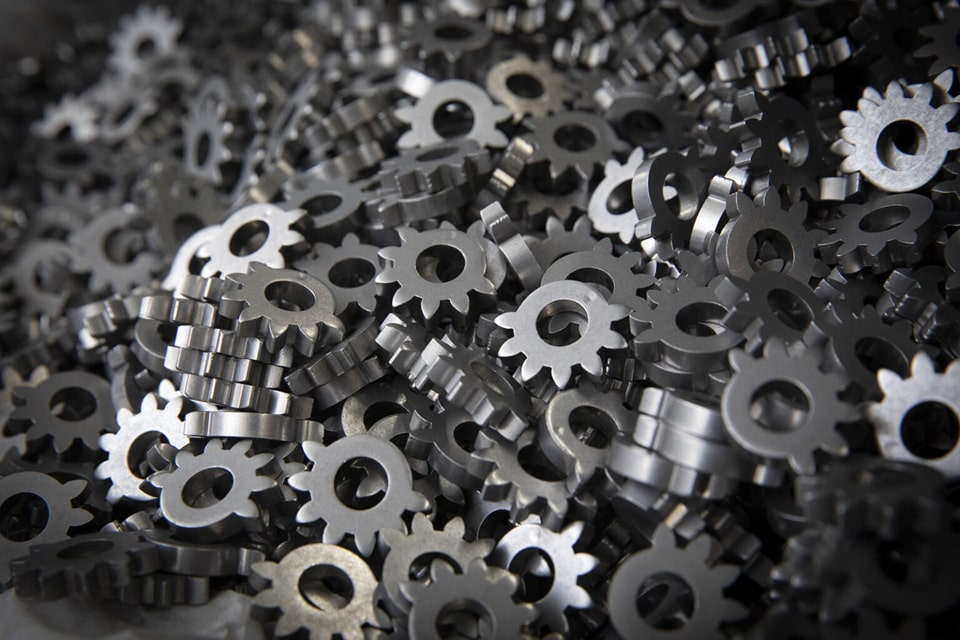

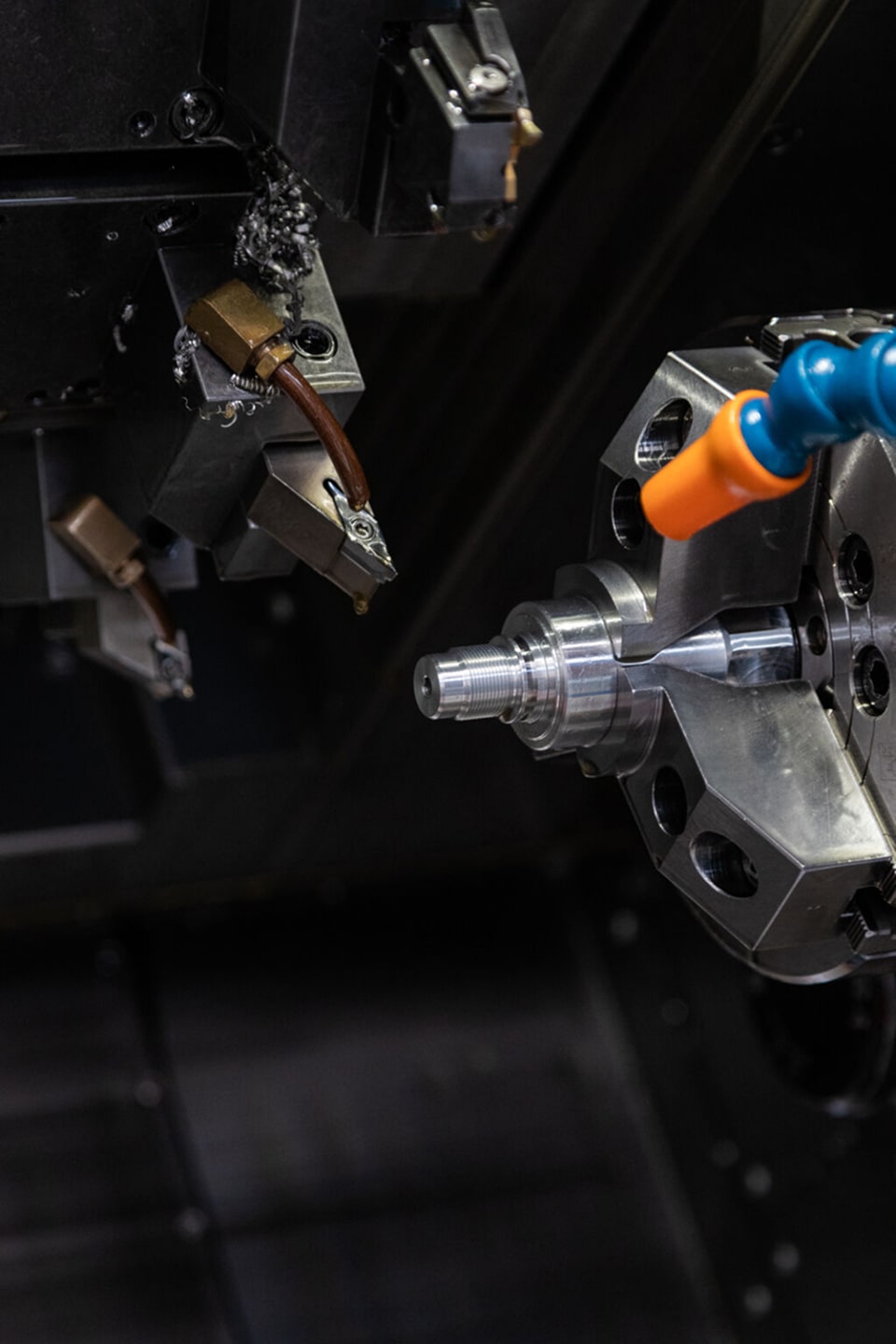

Metal is a key technology in the manufacture of high-precision metal components for the automotive industry. Teknia, as a multi-technology supplier with extensive experience in tube forming and metal stamping, integrates both areas of expertise under this technology to offer complete and efficient solutions to its customers. Its technical and production capacity makes the Group a trusted partner for the leading OEMs and TIER-1 companies in the sector. - Machining

This production technique allows Teknia to give specific characteristics and appearances to metal components, such as cylindrical parts, shafts, and other symmetrical shapes. Using this technology, the Group manufactures camshaft end pieces, which are the ends of camshafts and rotor or armature shafts, as well as various machined engine components and HVAC connectors.

With design and development capabilities for these products and means of production in both Europe and America, Teknia is ready to meet the demands of its customers internationally.

Commitment to new mobility and the environment

In an society that is moving towards a more responsible future that is conscious of environmental impact, Teknia stands out as an example to follow in the automotive components industry. Beyond its commitment to developing innovative mobility solutions, the Group also works actively to generate a positive impact on people and the environment, aligning itself with global sustainability goals.

Teknia is actively working to achieve carbon neutrality in its operations, with a firm commitment to reducing its environmental footprint and promoting responsible practices throughout its supply chain and production processes. In this context, in recent years the company has promoted various initiatives focused on energy efficiency and the circular economy.

Examples of this include the installation of variable speed drives in equipment, which has reduced energy consumption, and the incorporation of recycled materials in products, helping to reduce environmental impact without compromising quality. The Group is also committed to implementing photovoltaic self-consumption facilities and the use of renewable energies.

Sustainability is not just a word for Teknia; it is part of its business strategy and has been integrated into the company’s culture and daily operations since its inception. All this with a clear objective: to be the leading partner in the manufacture of solutions for sustainable, safe and innovative mobility. Find out more in our latest Sustainability Report.

Teknia’s multi-technology offering, highly qualified human capital, competitive production processes and advanced capabilities for manufacturing automotive components enable the company to meet the specific needs of its customers globally. All this while combining innovation, efficiency, quality and social and environmental responsibility.

Plants specialised in powertrain

Brazil

Rzeszów

Barcelona

Elorrio

Pedrola

Santander

For any questions, send us an email

Get to know our technologies