Looking to the future

In recent years, a commitment to sustainability has made its way throughout industry. The automotive sector is no stranger to this trend, with electric vehicles taking an increasing share of the market. As a result, automotive manufacturers and component suppliers have to adapt quickly to all these emerging developments.

In essence, we are in an environment of significant change for the sector, where factors such as lightweighting, bio-based raw materials or the incorporation of vegan alternatives to leather have gained greater prominence. This affects the processes and technologies for developing and manufacturing new products, putting companies’ ability to adapt to these changes to the test.

It is, therefore, a moment in history full of challenges, but also of opportunities in the new mobility industry that Teknia is determined to seize by expanding into new projects. The Group is ready to offer its manufacturing solutions as a multi-technology partner.

The accumulated know-how and experience enables the spanish company to offer innovative manufacturing solutions for customers worldwide. From the manufacture of new products to co-development with customers through the advanced manufacturing department, in order to shape the mobility of the future.

Multi-technology offer to lead the way in electrification

One of the cornerstones of the new mobility is electrification, not only in the automotive sector, but in urban mobility in general. There are huge opportunities for Teknia in this field, as the company has the capabilities to support this technological change and position itself alongside the leading manufacturers of components for electric vehicles.

This is possible thanks to its specialised technologies, including:

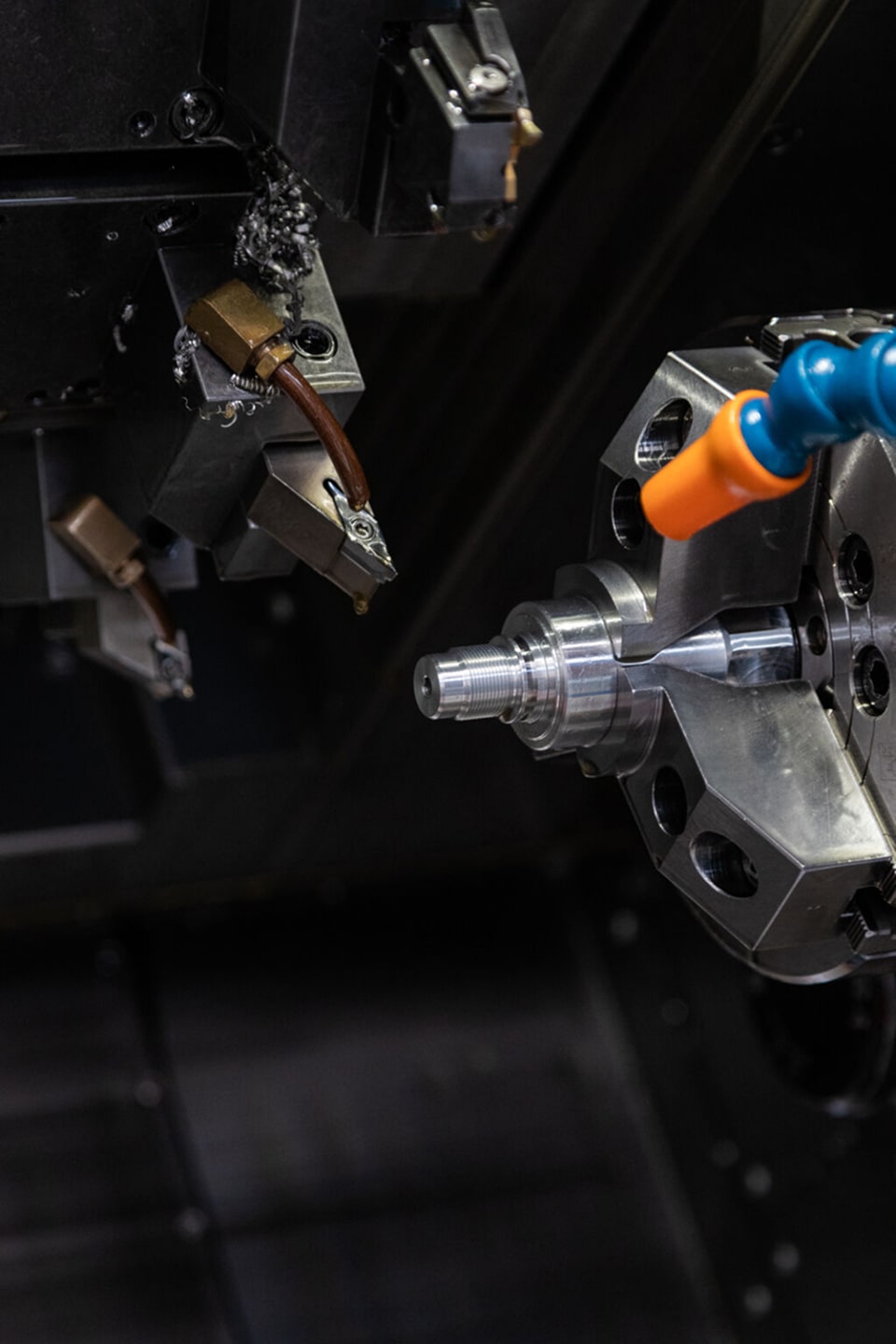

- Machining, a technique that allows metals to be given a specific appearance and characteristics, creating cylindrical parts, shafts, screws and other symmetrical shapes.

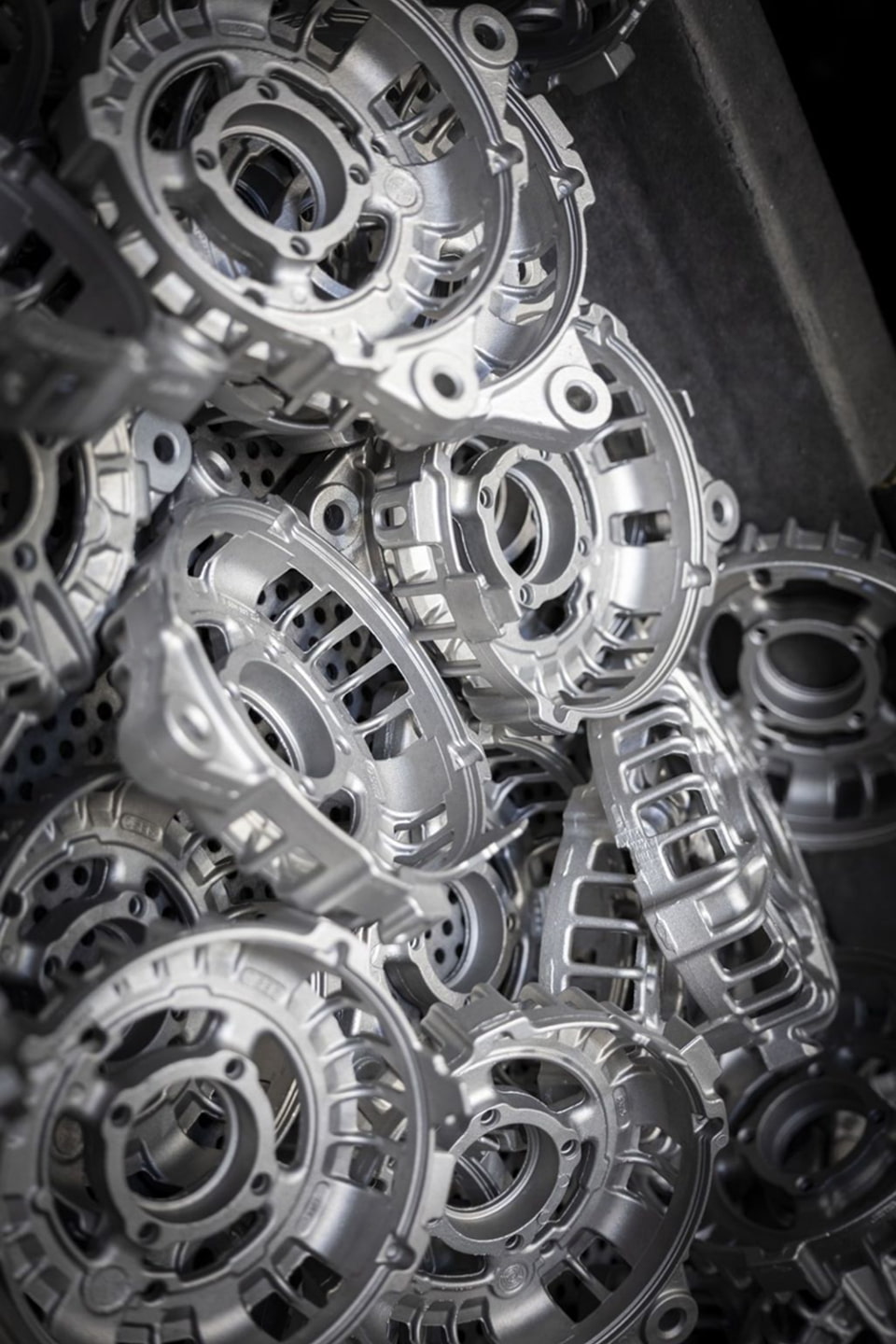

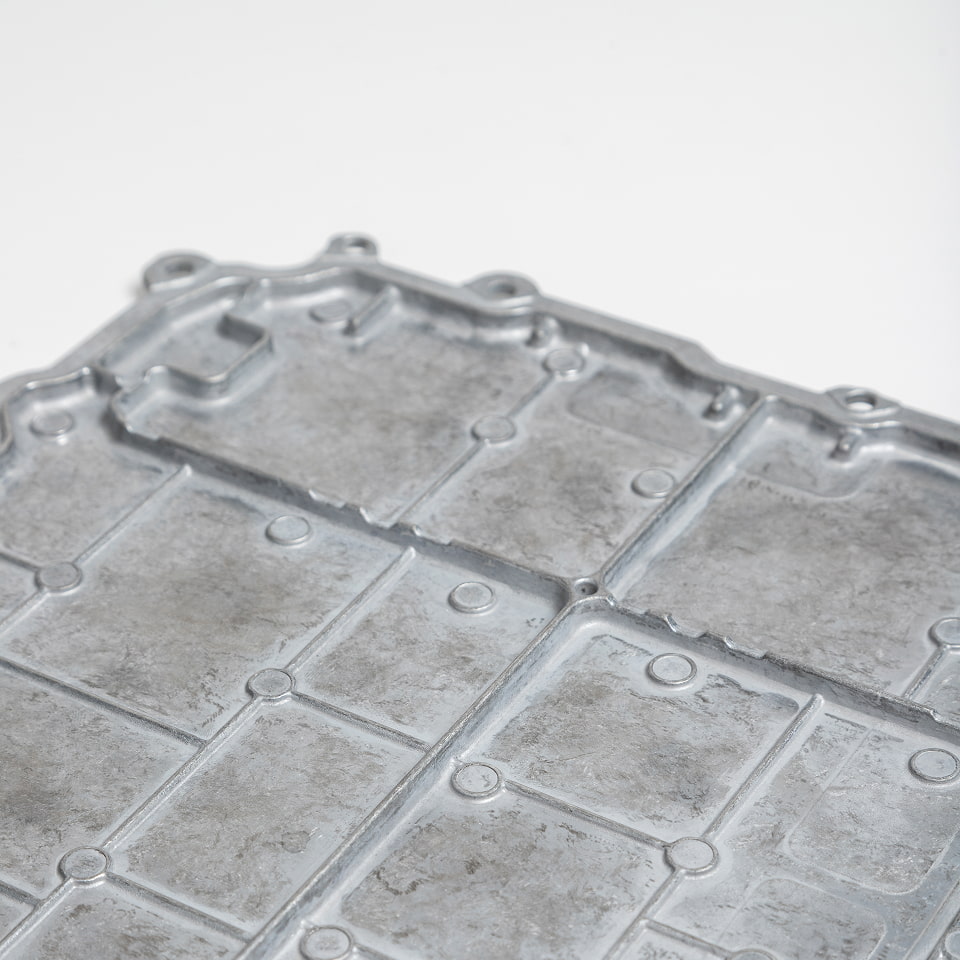

- High Pressure Die Casting (HPDC), used for the production of specific aluminium components with high precision and quality. Teknia is currently developing new welding solutions for electrical components for use in inverters, which require the cooling plate to be welded to its HPDC casing using friction stir welding (FSW) technology.

- Plastic injection, one of the key technologies within Teknia’s multi-technology offer to provide innovative mobility manufacturing solutions for safety, interiors and electronics.

Teknia also has the necessary specialisation to develop complex assemblies or components that combine several of these technologies and their assembly. This is the case of the collectors (HPDC + shaped tube + welding/assy); the resonators (HPDC + shaped tube + assembly) or the oil collection tube (shaped tube + stampings + assembly), among others.

Components for the new mobility manufactured by Teknia

In line with its commitment to sustainability and its innovative perspective, Teknia is working to enter the battery market in Europe, the powertrain environment and its components.

Some of the parts developed by Teknia are:

- Inverters and converters.

- On-board chargers (OBC).

- Battery elements, such as inserts.

- A wide variety of components required for the use of electricity as a propulsion system in vehicles, from housings or hard cases to trims.

It should be noted that the company’s highest level of specialisation is in stamped (modular and welded) battery cooling plates and busbars (stamped + overmoulded + assembled); as well as HPDC for inverter and converter housings, stamped inverter covers, ECU’s and electronic control units, which can be manufactured in HPDC, stamping and plastic. Also inserts for plastic battery housings.

Teknia, a key player in the new mobility

Components for Teknia’s new mobility are produced in a wide variety of production plants:

- HPDC factories manufacture covers and housings.

- Teknia Elorrio develops embouts (connectors) and cooling tubes.

- Teknia Manresa manufactures busbars and covers for inverters and ECUs.

- Teknia Kalisz produces cooling plates.

- Teknia Bilbao manufactures inserts for plastic battery casings and embouts.

- Teknia Santander is a production centre that stands out for its expertise in the manufacture of shafts for electrical components.

Teknia Santander has been one of the most recent to become part of the company and its acquisition has allowed the integration of new technologies and the expansion of the product and service offering, complementing the existing plastic injection, stamping, tube forming and bar turning technology.

The acquisition of the plant located in Ampuero is part of Teknia’s strategy to expand its presence in the electric vehicle components sector, reinforce its commitment to sustainability and strengthen its production capacity in key technologies such as aluminium injection and bar machining.

Additionally, Teknia Santander is involved in wider sustainability projects within the Group. This is the case of the responsible self-consumption project, which involves the installation of solar panels to guarantee a significant percentage of electricity from renewable sources.

Focus on environmental care

Teknia not only strives to develop components for new mobility, it also seeks to contribute to a positive impact on people and the environment. Its goal is to achieve climate neutrality and offer customers carbon neutral products, improving the efficiency of all processes. In this line, Teknia Martos (Spain) has become the first carbon neutral plant in its operations.

In recent years, Teknia has established various lines of work that promote energy savings and the circular economy in the supply chain of its factories. This is the case of the installation of inverters in equipment to reduce consumption or the use of recycled materials that do not affect product quality, but contribute to reducing the Group’s environmental footprint.

Thanks to the improvements implemented, emissions intensity has been reduced by more than 13%. Furthermore, all the energy consumed comes from sustainable sources of supply, while significant savings in electricity consumption have been achieved through photovoltaic self-consumption installations.

In short, sustainability is integrated into the Group’s business strategy and has been part of the company’s day-to-day operations and people since the very beginning. The goal? To be the best partner for mobility manufacturing, offering sustainable, safe and innovative solutions. You can find more information in our latest Sustainability Report.

The combination of innovative technologies, highly skilled personnel, highly competitive production processes and advanced capabilities for the manufacture of high quality components for the automotive industry ensure that Teknia is well positioned to grow as the new mobility market evolves.

Plants specialised in new mobility

Kalisz

Ampuero

Azuqueca

Bilbao

Elorrio

Manresa

Santander

For any questions, send us an email

Get to know our technologies