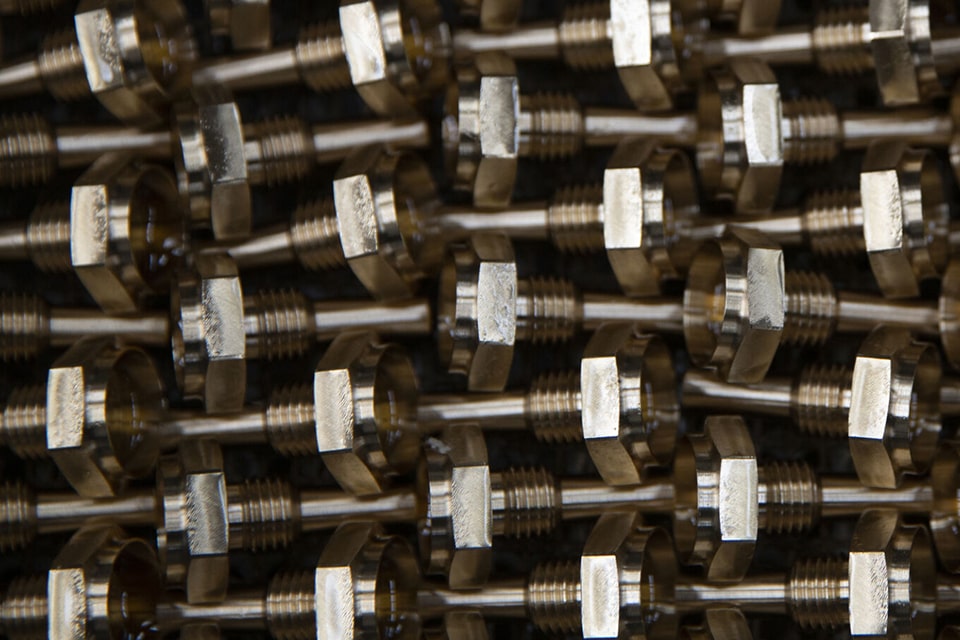

The high degree of experience and specialisation in machining gives Teknia the possibility to manufacture very different types of components through this technology. Our bar turning machines, both multi-spindle and single-spindle, allow us to offer customers different diameters in the final product, using a variety of materials in the process.

Machining technology

Machining technology comprises a broad set of high-precision techniques and processes used to shape materials, usually metals. It is carried out by the controlled removal of excess material, with the aim of achieving the specific shape, dimensions and characteristics desired in the final product. It is, in essence, a fundamental process in the manufacture of cylindrical parts, shafts, screws and other symmetrical shapes.

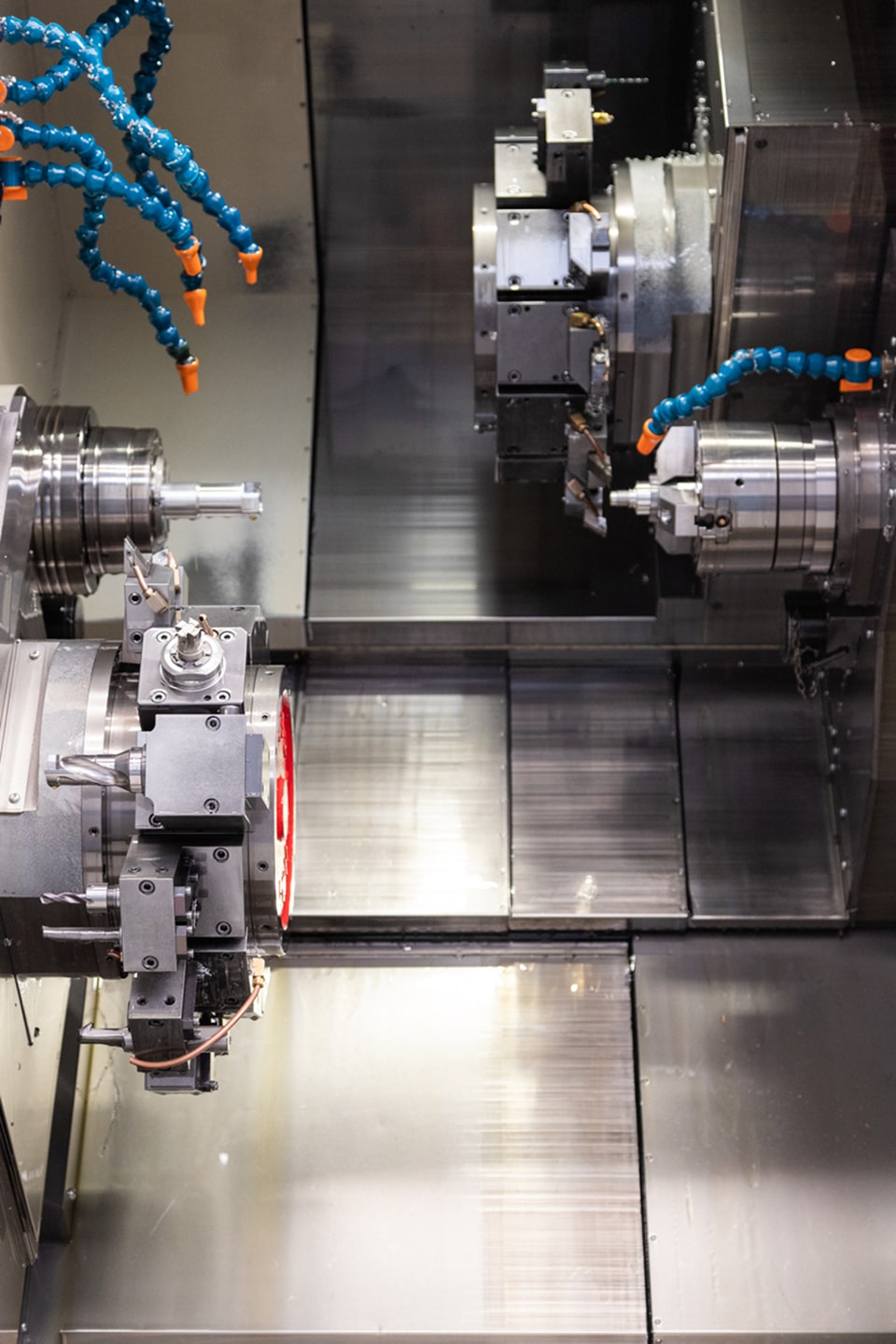

Specifically, the machining technology that Teknia employs is known as chip removal turning. As its name suggests, turning is based on the use of lathes (single or multi-spindle) in the bar machining process. This technique consists of introducing a bar into bar turning machines, which apply a rotational movement to bars of different sections.

As the cutting tool moves along the surface of the bars, it removes the metal in the form of chips, until the desired shapes are achieved. In the processing zone, the raw material may pass through one or more machining stations, depending on the final product. Each station gives the raw material a specific shape and characteristics until it reaches the final station, where the part is cut and finished.

This technology allows the production of high-precision metal parts with an excellent finish at high production rates. In addition, the use of lathes allows high production flexibility, as these tools are easily adaptable to different part geometries and materials. Alternatively, Teknia has production means that allow the machining of unitary parts starting from a preform.

In the machining business unit, Teknia focuses mainly on machining tubular profiles and hexagonal solid cylindrical bars. The company works with sizes up to 65 millimetres, in all cases of a metallic nature. The materials used include leaded and lead-free aluminium, steels of different alloys, stainless steels and leaded and lead-free brass.

Advanced manufacturing technologies

Teknia, in any of its production plants, is capable of manufacturing revolution components using automatic cam lathes. This technology is common in the manufacture of simple parts at low cost. In short, the company has been evolving in recent years towards the numerical control of units installed on automatic lathes on an ad hoc basis. Thanks to this, Teknia is able to carry out operations with a higher level of precision and complexity.

In addition, the Group has innovative machines equipped with 100% CNC (Computer Numerical Control) manufacturing technology, which automate the machining process. Together with the creation of new shapes that go beyond those manufactured by revolution, they allow for greater precision, speed and efficiency in the manufacture of components.

This aspect is highly valued by customers, which include both OEMs and Tier-1 manufacturers. The technologies that can be found in Teknia’s production plants are:

- Teknia Bilbao has CNC fixed headstock single-spindle lathes up to Ø64, with ‘Y axis’. It is also equipped with multi-spindle mechanical lathes up to Ø20 and CNC up to Ø51. Recently, drilling and milling technology with high-frequency spindles has been incorporated for machines without this option.

- Teknia Stuttgart mainly uses Swiss-type single-spindle lathes up to Ø42; fixed-spindle single-spindle lathes up to Ø65 with ‘Y-axis’ and ‘B-axis’; and CNC eight-spindle multi-spindle lathes up to Ø42 with ‘Y-axis’. It also integrates CNC grinding machines with robot and assembly machines.

- Teknia Barcelona has incorporated smaller diameter CNC multispindles to improve finishes and reduce manufacturing cycle times. The plant is equipped with CNC multispindles up to Ø40 with double counter spindle and ‘Y-axis’; Swiss-type single spindles up to Ø26; a four-axis machining centre; plongee centreless grinding machines with CNC robot and through centreless grinding machines. In short, the parts milling process has been integrated as part of the factory’s production potential.

- Teknia Santander has a transfer machine with Ø32 bar loader; CNC single-spindle lathes up to Ø52 with 3 turrets and ‘Y axis’; CNC multi-spindle lathes up to Ø50 and automatic lathes up to Ø32. In addition, it is equipped with CNC centreless grinding machines, rolling machines, gear hobbing machines, induction hardening equipment and three-axis machining centres.

Ultimately, Teknia is integrating new processes into the lathe and is actively working on the search for parts that require new production processes. Manufacturing methods that add singularities to machining and give companies the possibility to move away from the most common on the market, thus creating business opportunities with greater added value.

Our products by machining process

Teknia supports its customers with many types of machining processes within the mobility sector. The highly complex components manufactured by the Group are suitable for any type of vehicle and cover a wide range of diameters from 5 mm to 65 mm.

Each of the production plants specialising in this technology develops a number of specific system components, which are integrated into the many end products demanded by customers globally. For example, Teknia parts are integrated into multiple sensor and chassis parts, as well as electrical and braking systems.

The Group also has extensive experience in the manufacture of brake pistons, a key safety part. In addition, the company specialises in axles, a strategic product with great growth potential. Teknia is currently working on different machining products for electrification.

Teknia guarantees the highest quality in its products

For Teknia, the quality of its products is a priority. For this reason, sample control patterns are applied throughout the production process at different intervals to ensure stable processes. The means of supervision employed by the company are varied, including vision camera control systems, physical probe control systems and human controls.

In the event that the multidisciplinary teams detect non-competent processes, detection and control systems are integrated on 100% of the parts, thus guaranteeing the quality of all the components sent to the customer. It should be noted that rigour in the analysis of the product vs. process, which helps to foresee risk factors, is vital to avoid possible deviations during manufacture.

This allows Teknia to focus control efforts on critical stages of the process and avoid errors during production. For example:

- The correct set-up of the processes and the monitoring of the capacity of the means to guarantee stable processes.

- Preventive maintenance of the machines and exhaustive control of tool changes to guarantee the correct quality of the parts.

- In those parts with more sensitive materials and/or geometries, correct handling of the part is key to guaranteeing the quality of the component.

- The handling design adapted to each need is essential, and may include unit handling by robots and specific cleaning tools.

- The design of the process and its control plan allows us to guarantee that the state of the production means is suitable for the product to be manufactured.

In addition, all Teknia’s production plants are IATF 16949 and ISO 14001 certified. The company is also working towards TISAX ISO27001 certification and, in the coming years, expects to achieve ISO 50001 certification for energy efficiency. Ultimately, it offers the ability to adapt to all standards and specific customer requirements, such as the VDA 6.3 audit.

Sustainability in all processes

Sustainability is a fundamental aspect of industry, economy and society. Therefore, Teknia seeks to generate a positive impact on people, the environment and governance, integrating sustainability into its business strategy. This has been part of the company’s day-to-day operations and people since its inception.

In order to become the best partner for mobility manufacturing through sustainable, safe and innovative solutions, the Group works to reduce the environmental impact of production with several lines of work that promote energy savings and circular economy in the supply chain.

In this regard, all the energy consumed comes from sustainable supply sources, while improving process efficiency with the implementation of filtering and cooling systems for cutting fluids. These allow a longer service life of cutting fluids, better preserve the life of cutting tools by reducing tool changes and reduce machine consumption.

In addition, the use of returnable packaging and the consumption of recycled raw materials in steel and aluminium is encouraged, with green energy supply sources. These do not affect product quality, but contribute to reducing the company’s environmental footprint. You can find more information in our latest Sustainability Report.

The high qualification of human capital, the use of efficient and competitive production processes, a multi-technology offer and advanced capabilities for the manufacture of high quality components are the key to the company’s success in the pursuit of excellence. Through innovation and adaptation to market needs, Teknia offers efficient and customised machining solutions at a global level, complying with the strictest international standards.

Plants specialised in machining technology

Barcelona

Bilbao

Santander

Stuttgart

Mexico City

For any questions, send us an email

Get to know our products