The Group’s wide range of technological solutions and global engineering capabilities enable it to adapt to both market trends and the needs of electric and autonomous vehicles. In short, Teknia has great potential in this product category.

Driving comfort, a product category with a bright future

Driving comfort is a product category that includes suspension, steering and transmission systems that make it possible to drive, turn and stop a vehicle. Teknia plays an important role in the manufacture of these essential components, which represent the ‘backbone’ of both current and future cars.

The Group has extensive experience in supplying driving comfort components and is an expert in providing global engineering solutions in the countries where it operates. As a multi-technology partner, Teknia has the technical knowledge and advanced capabilities to offer innovative manufacturing methods for vehicle suspension, steering and transmission assemblies.

With an eye to the future, the company is currently expanding its business and adapting to the manufacture of specific components for new mobility solutions. These range from new products to full co-development with customers through the advanced manufacturing department, with the aim of shaping the mobility of tomorrow.

Multi-technology offering in component manufacturing

The Group offers its customers solutions using different technologies and in multiple geographical areas, both in Europe and America, while adapting to market trends. As a result, Teknia has great potential in this product category.

Driving comfort components are represented in the various technologies offered by the company, with parts for steering columns and parts for the suspension and damping system, among other elements:

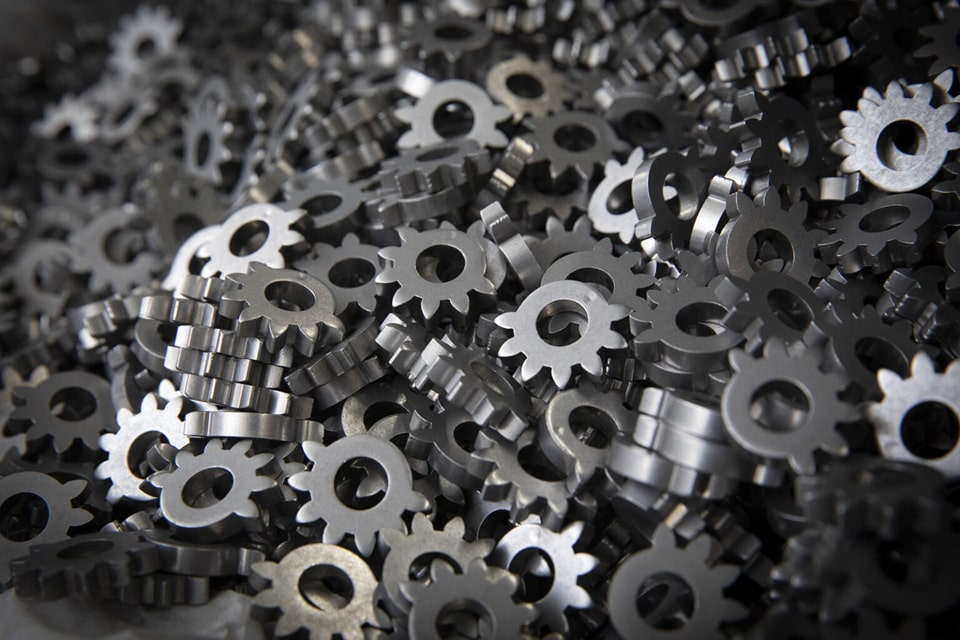

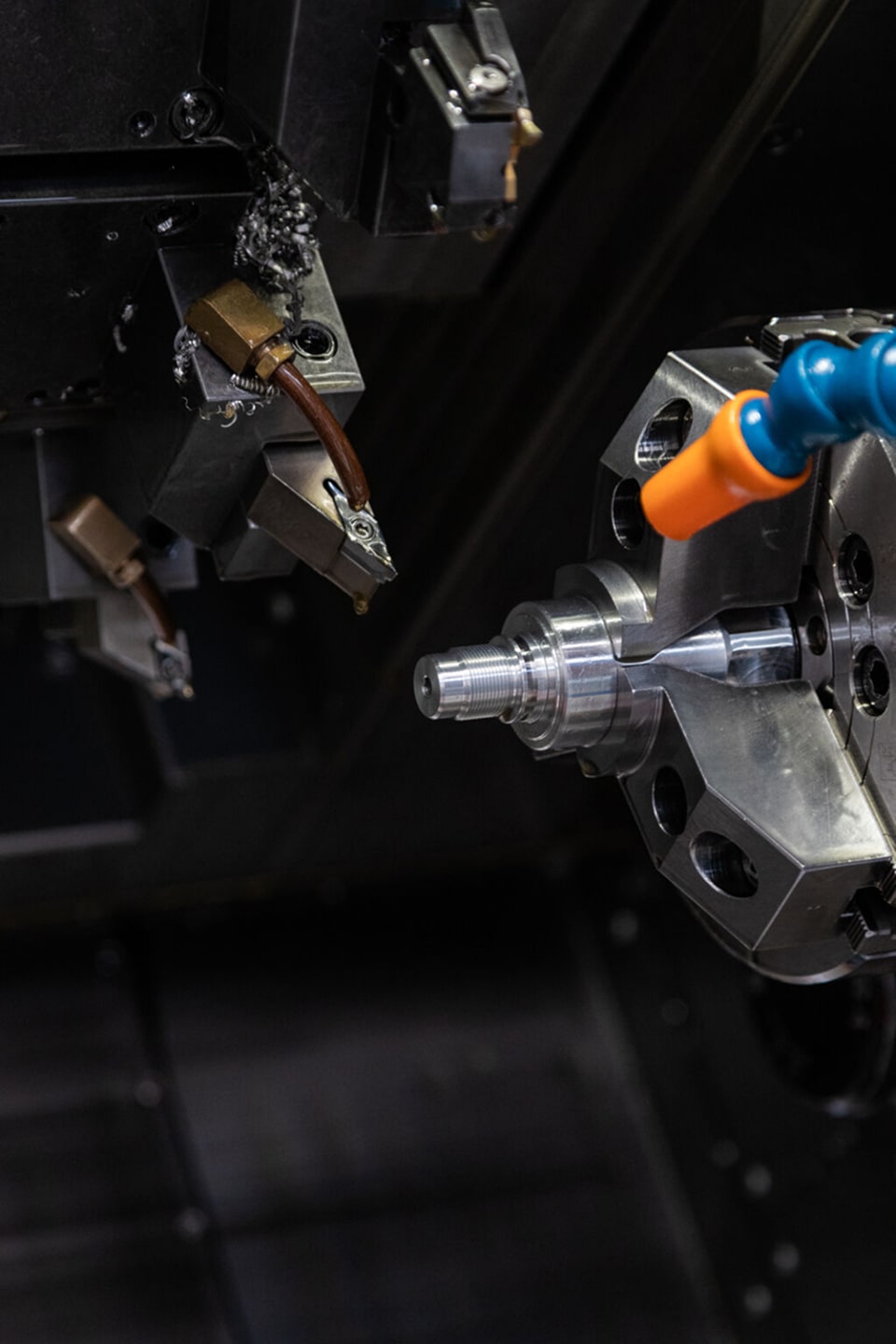

- Machining, a technology that allows metal bars to be given a specific appearance and characteristics through rotational transformation. This process is particularly important in the Driving Comfort category, specifically to achieve the necessary and definitive shapes and tolerances required for parts such as the magnetic housing of the adaptive suspension for the most demanding and premium vehicles. Axles that facilitate assisted steering movements are also developed and manufactured.

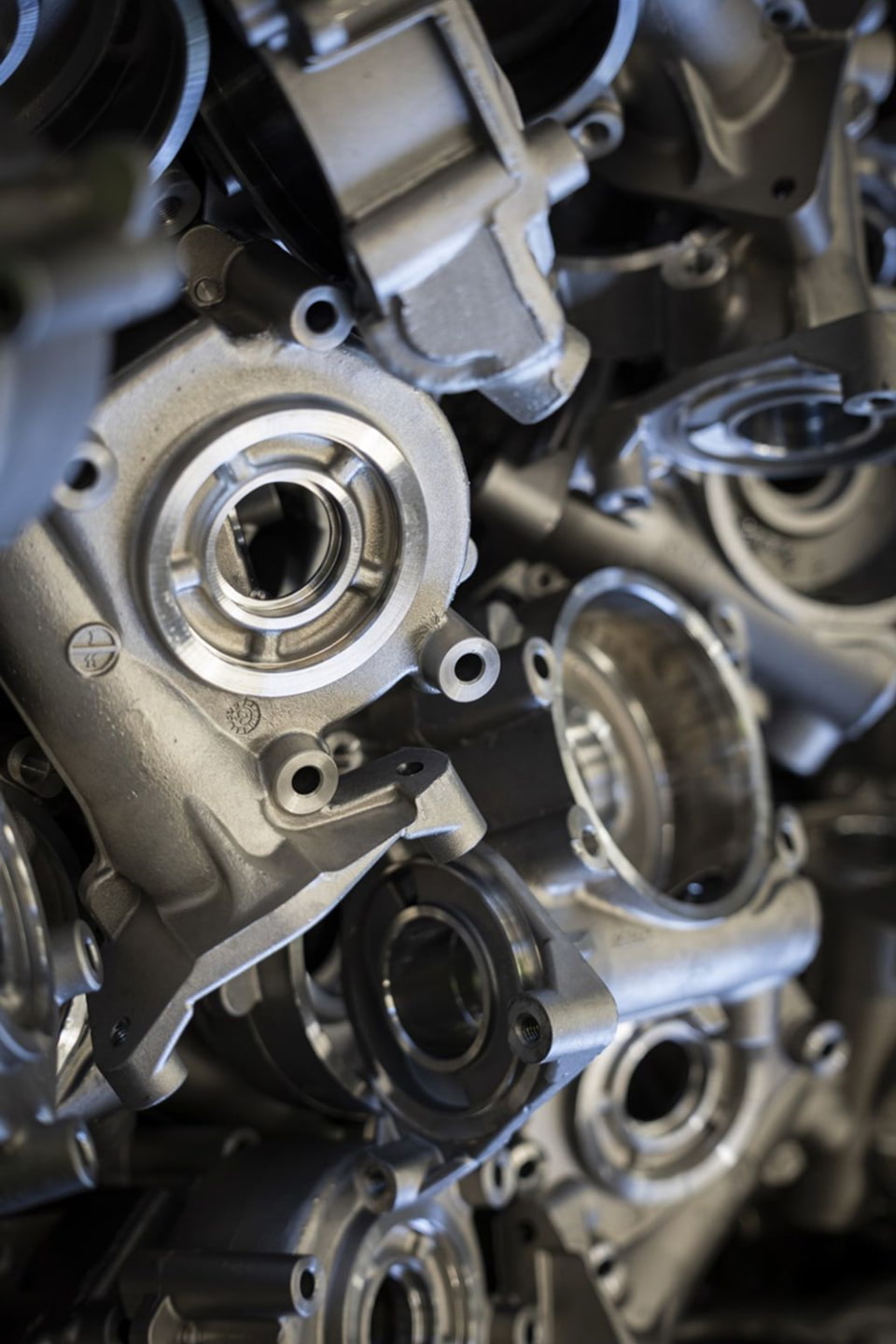

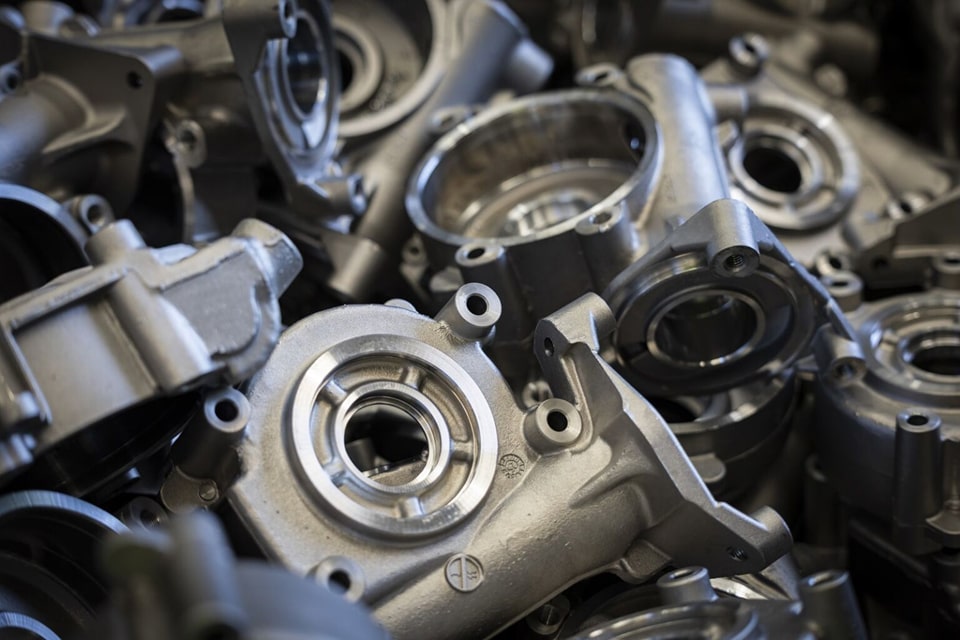

- High-pressure die casting (HPDC), essential in the production of specific aluminium components for suspension and steering assemblies with high precision and quality. This technology is particularly important in the manufacture of the jacket body, where the entire steering system is attached, and the housing for the electronics that control the power steering.

- Metal is a key technology in the manufacture of high-precision metal components for the automotive industry. Teknia, as a multi-technology supplier with extensive experience in tube forming and metal stamping, integrates both areas of expertise under this technology to offer complete and efficient solutions to its customers. Its technical and production capacity makes the Group a trusted partner for the main OEMs and TIER-1 companies in the sector.

Manufacturing technologies for Driving Comfort products

The Group also has the necessary expertise to develop complex assemblies or components that combine several of these technologies and their assembly. The steering column is a perfect example of this, as this assembly requires a high-pressure aluminium injection body, tube sleeve, stamped brackets and overmoulded plastic levers.

Driving comfort components manufactured by Teknia

Teknia currently manufactures a key product for steering systems: the servomotor housing. This component is manufactured at various locations around the world, and the Group is working to reach new customers.

In terms of suspension, the Group manufactures spring seats, lower supports and upper supports. These parts form part of the shock absorber. Teknia also develops high-end suspension components that will be of great importance in the vehicles of tomorrow.

With regard to the transmission assembly, Teknia manufactures the transmission tube and the gear lever housing. It does so using its own transfer lines, which it designs and manufactures itself.

Steer-by-wire, key to Teknia's differentiation

Teknia’s global presence and multi-technology expertise set it apart from other component suppliers, especially in the area of steering. One of the most important technological advances that the company has incorporated into the Driving Comfort category is related to electronic steering, a major trend in the field of mobility.

Essentially, this system represents a fundamental change in the way we interact with vehicle steering, where electronics play a leading role. Teknia, as a leader in the manufacture of technological components, manufactures a key product for Steer-by-Wire systems: the servohousing.

Given that electronic addresses offer numerous advantages in terms of efficiency, security and convenience, the servohousing developed by Teknia is a key component in current and future vehicles. It is an innovative product that is highly demanding in terms of quality and specialisation. Without a doubt, its characteristics make it a clear example of the company’s industrial and technological spirit.

Process efficiency and respect for the environment

In an environment that is moving towards a more responsible future that is conscious of its environmental impact, Teknia works not only to develop components for more sustainable mobility. It also seeks to generate a positive impact on people and the environment, with the aim of achieving climate neutrality and offering customers carbon-neutral products.

Teknia actively works to improve the efficiency of all its processes. In its firm commitment to reducing its environmental footprint and promoting responsible practices throughout its supply chain and production processes, in recent years the company has established different lines of work that promote energy saving and the circular economy in its production plants.

Examples of this include the installation of variable speed drives in equipment to reduce energy consumption, as well as the incorporation of recycled materials in products. In this way, the Group reduces its environmental impact without compromising quality. Teknia is also committed to the implementation of photovoltaic self-consumption installations and the use of renewable energies.

Thanks to the improvements implemented, emissions intensity has been reduced by more than 13%, enabling the company to offer safer, more innovative and, above all, more sustainable solutions. Sustainability has been part of Teknia’s DNA since its inception, seeking to become the best partner for manufacturing more efficient and environmentally responsible mobility. Find all the information in the Sustainability Report.

Teknia stands out in the automotive sector for its high level of multi-technology expertise and its ability to centralise the production of different technologies in a single supplier. Its strategic presence in the industry’s main production centres, its proximity to customers and its high level of service and quality ensure that the company is prepared to meet its customers’ needs in the category of driving comfort for new mobility, both in interurban areas and in the cities of the future.

Plants specialised in Driving Comfort

Stuttgart

Kalisz

Oradea

Ampuero

For any questions, send us an email

Get to know our technologies