In addition to the technical know-how of our teams, we have decades of experience in development and manufacturing, which enables us to create an end product of excellent quality and high added value. Components capable of adapting to the standards and needs of manufacturers and large automotive suppliers located in many different geographies.

Tube forming

Tube forming is a process that consists of the cold deformation of the material in order to mould it to the geometry required by the customer. Starting from metal tubing, in which materials such as carbon steel, stainless steel and aluminium predominate, we apply advanced technologies that allow us to create different types of tubular assemblies for some of the main parts of the vehicle.

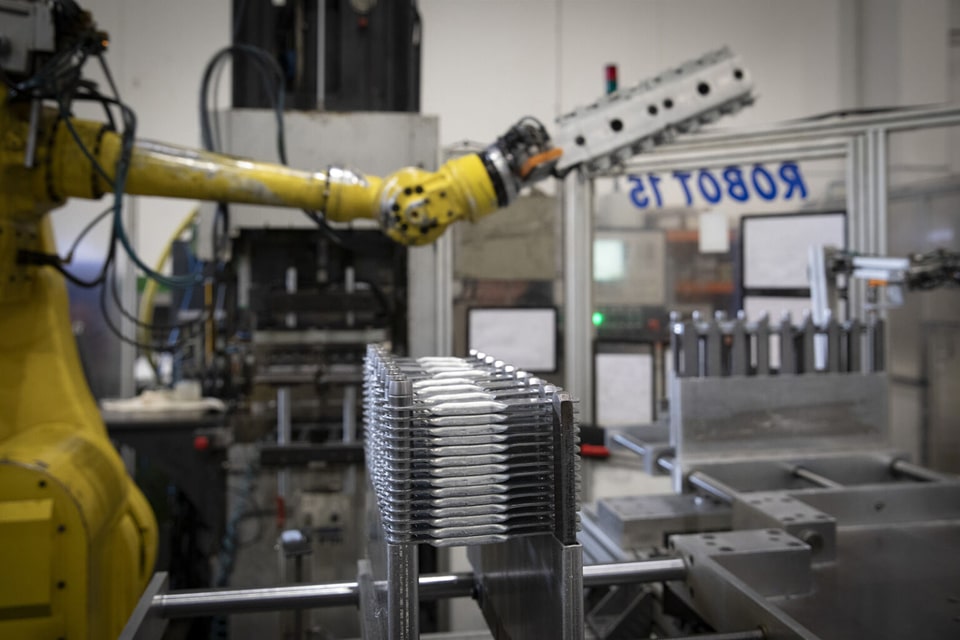

In order to offer a differential service, maintain the increasing level of competitiveness demanded by the market and excellence in quality, Teknia relies on the experience in the design and construction of its own machines. These machines achieve the right shape in tube forming processes and provide a great competitive advantage in high volume projects thanks to their complete automation.

Development of key vehicle safety parts

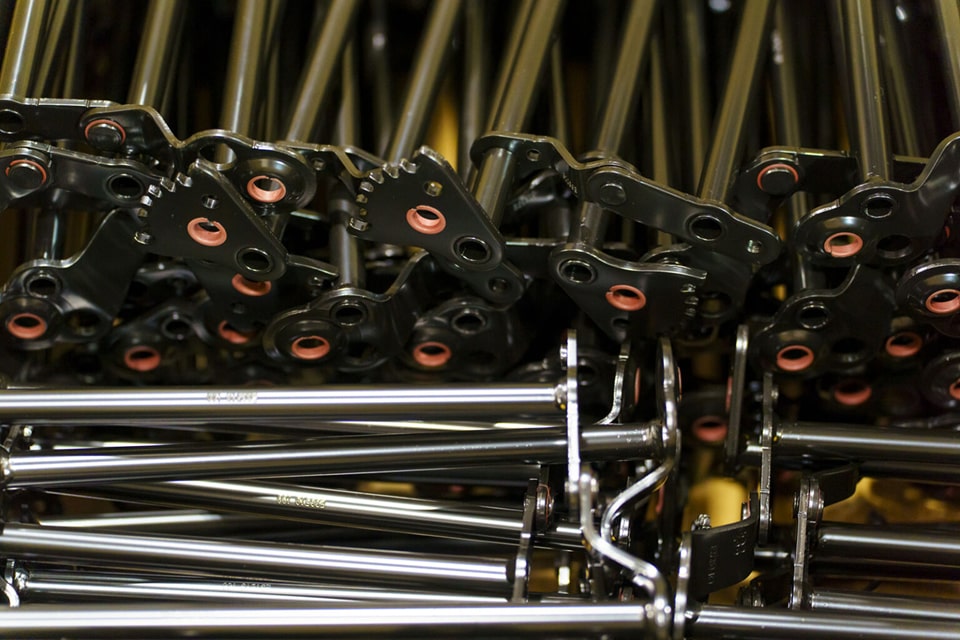

Among the components manufactured by the Group are engine cooling and oil pipes, seating mechanisms (reclainers & towel bars), headrests, seat belt pre-tensioners and other automotive components.

Elements that require high strength and durability, as they play a key role in passenger safety. For this reason, at Teknia we ensure the highest quality thanks to automatic control stations integrated in the machines themselves.

Stamping

Stamping technology is a manufacturing process that makes it possible to obtain metal parts by deformation of the starting strip. The process takes place by subjecting the material to shear stresses that exceed its elastic limit, achieving permanent deformations in its shape. Specialised presses are used to carry out the metal forming by applying force and pressure.

Therefore, this process may include various operations, such as cutting, bending or punching. It should be noted that stamping technology is carried out with a variety of advanced machines, including high-precision presses. In particular, Teknia has high tonnage presses – up to 1000 tons – which are capable of applying large amounts of pressure on the material.

Importantly, our Computer Numerical Control (CNC) presses allow the execution of complex programs, which control the movement of the stamping tools. This ensures consistent, high quality manufacturing of our products. In addition, they are equipped with automated material handling systems, enabling the manufacture of components with high levels of precision and efficiency.

External vehicle and safety components

Metal stamping technology is widely used in the automotive industry to produce both structural and body components, as well as numerous safety systems and various fasteners. It is an ideal process for the manufacture of components that do not require extreme strength characteristics.

In addition, it offers significant advantages, such as higher production speed and improved surface finish. Coupled with complementary technologies such as plastic overmoulding, it opens the door to an interesting range of products with high added value.

Some of the high precision and high quality finishing components we develop in Teknia are:

- Safety components such as Horn Plate or Airbag Housing.

- Mechanisms: door and bonnet hinges, armrests…

- Suspension components such as Lower Brackets and Spring Seat.

Related products

International technology

Metal stamping process represents Teknia’s versatility and international capacity to offer high quality solutions using this technology. It can be found in the plants of Teknia Manresa and Teknia Pedrola in Spain, Teknia Kragujevac in Serbia, Teknia Kalisz in Poland, Teknia Brazil and Teknia Nashville in the United States.

These plants are equipped with high tonnage presses and automated material handling systems. As a result, we achieve efficient and precise manufacturing of automotive components for customers all over the world. Each of these plants plays a crucial role in supplying specialised products to local and global markets.

Complex component assembly

At Teknia we are experts in tube forming technology and the stamping of small and medium-sized metal components for different types of assemblies. We also have advanced capabilities to make complex assembled products from parts developed by combining these technologies.

The inclusion of additional components and processes, such as sheet metal welding, automated assembly, overmoulding or bushing insertion, allows these components to be integrated into complete systems. Furthermore, this integration of technologies optimises manufacturing efficiency and improves component performance.

Some assembled sets, including stamped components and formed tubes, are used in a variety of automotive applications. For example, suspension systems, seat structures and safety components. These are all products where high precision, strength and quality are guaranteed.

In short, thanks to the creation of synergies between the different production plants and the technologies available in the Group, we are able to manufacture different types of products with high added value, provide comprehensive solutions to our customers and have a presence in the different areas of a vehicle.

An example of a complex assembly is the crash cage manufactured at Teknia’s factory in Pedrola, a clear demonstration of the Group’s capacity to manufacture complex assemblies. This component, which is crucial for occupant protection in the event of a crash in hybrid vehicles, is assembled using sophisticated forming and welding techniques.

Overmoulding: the joining of plastic stamping and injection moulding

Teknia’s added value reaches its maximum expression in the combination of various technologies, overmoulding being a good example of this. This is a manufacturing technique that combines stamping technology and plastic injection with the aim of producing complex, high quality components.

This technique is used to improve the mechanical and aesthetic properties of parts, as well as to add additional functionality. For example, insulation or cushioning. The overmoulding process is carried out in several stages: first, the metal part is stamped and then placed in an injection mould where the plastic is added.

Basically, overmoulding consists of applying a layer of plastic material on top of a previously stamped metal part. This allows different materials to be integrated into a single component, such as the Hornplate. This is a sensitive and complex safety part installed in almost all steering wheels of all car manufacturers.

In short, it is a multi-technological and very demanding product in terms of quality, which represents the industrial and technological spirit of Teknia. And if there is one thing that characterises the company, it is its constant innovation and adaptation to new market trends. Teknia invests continuously to improve its manufacturing processes and equipment.

Ultimately, it should be noted that all the processes and technologies involved in overmoulding are united under one roof. This leads to lower manufacturing and supplier management costs for customers, better quality control and a significant reduction in CO2 emissions.

Efficient processes as a key to success

Not least, sustainability plays an essential role in Teknia’s production processes, based on process efficiency. The latest innovations include:

- Servo-controlled engines, which reduce the consumption of environmentally harmful oils.

- Modern lubrication systems, which allow a better oiling process.

- State-of-the-art machines with reduced air consumption and pneumatic leakage measurement and control systems, which reduce energy consumption.

In summary, Teknia is a leader in the combination of technologies, with highly competitive production processes and advanced capabilities for the manufacture of high quality metal components for the automotive industry. Through innovation and adaptation to market needs, the Group continues to offer efficient and customised solutions globally for the new mobility and electrification of vehicles.

Plants specialised in metal

Manresa

Kragujevac

Pedrola

Kalisz

Nashville

Brazil

Elorrio

For any questions, send us an email

Get to know our products