The company’s global engineering capabilities, multitechnology offering, and versatility in equipment for the manufacture of exterior vehicle components allow Teknia to meet the highest customer demands and position itself as a leader in this product category.

‘Exteriors’, an essential product category in every vehicle

Most of the vehicles currently marketed feature a monocoque concept that integrates the most relevant exterior parts: the body and the chassis. These form the base structure that supports the vehicle’s mass, providing the necessary space to assemble other key vehicle components.

As highly resistant metal structures, they give the vehicle the desired support, rigidity, and shape. Both are essential components in all current automobiles, and they will continue to be so in the vehicles of the future. As the industry moves towards more sustainable mobility, component suppliers are introducing lighter and stronger materials into production.

Thanks to its stamping capabilities, Teknia participates in the manufacture of these parts, producing components that are integrated into both traditional vehicles and new mobility solutions. The Group’s innovation, rigor, and quality in materials and technologies enable it to meet its customers’ needs worldwide.

Stamping, key in the ‘Exteriors’ category

Teknia has great versatility in its equipment for the manufacture of exterior vehicle components. In this product category, the company offers extensive experience in two crucial technologies: metal component stamping and plastic injection.

Among the most significant technological advances that the company has incorporated in this category in recent years are the expansion of the global presence of stamping and overmolding capabilities, as well as vertical and horizontal integration in technology, with the specialized vision of global industry leaders.

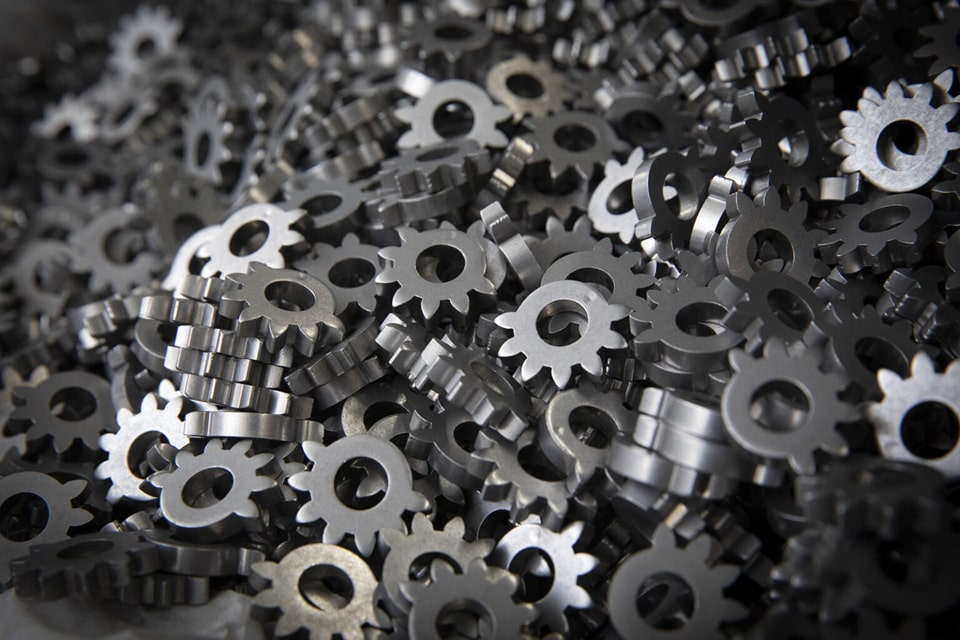

Stamping of metal components

Stamping is a process that allows complex metal parts to be obtained by subjecting the material to shear stresses that exceed its elastic limit, achieving permanent deformations in its shape. For this, tooling known as dies is used, which contain the shape to be given to the part.

Teknia has a wide range of presses, reaching up to 1,000 tons. This allows the company to cover a significant portion of its customers’ needs. It is also worth highlighting that this method offers significant advantages, such as higher production speed and better surface finish.

Furthermore, by combining stamping with other complementary technologies available within the Group, such as plastic overmolding, welding, or assembly forming,Teknia can offer highly competitive manufacturing processes and a broad range of products that stand out for their high added value and global capabilities.

Some high-precision, high-quality products in the ‘Exteriors’ category that Teknia develops through metal stamping include components for front and rear wipers, door hinges, brake pedals, various chassis components, and more complex body mechanisms such as sunroof subassemblies.

It should be noted that the stamping process represents Teknia’s versatility and international capacity to offer high-quality solutions through this technology. Vehicle exterior components are produced at Teknia Manresa and Teknia Pedrola plants in Spain, Teknia Kragujevac in Serbia, Teknia Kalisz in Poland, Teknia Brazil, and Teknia Nashville in the United States.

These plants are equipped with high-tonnage presses and automated material handling systems. As a result, Teknia achieves efficient and precise manufacturing of automotive components for customers around the world. Each of these plants plays a crucial role in supplying specialized products to local and global markets.

Technologies related to exterior products

Commitment to sustainability

Sustainability is integrated into Teknia’s business strategy and has been part of the company’s daily operations and culture since its origins. As we move toward a future that is more environmentally conscious and responsible, the Group not only focuses on creating components for sustainable mobility but also strives to make a positive impact on people and the environment.

The objective is to achieve climate neutrality and provide customers with products that are completely carbon neutral. As part of this commitment, Teknia is continuously improving the efficiency of all its processes, working to reduce its environmental footprint and promoting responsible practices throughout its supply chain and production.

In line with this, in recent years the company has developed various initiatives that promote energy savings and circular economy practices in its factories. These include the installation of frequency converters in equipment to reduce energy consumption, as well as the use of recycled materials in products lowering environmental impact without sacrificing quality.

Furthermore, Teknia promotes the use of self-consumption photovoltaic installations and the adoption of renewable energies. Thanks to the improvements implemented, emission intensity has been reduced by more than 13%. This enables the Group to offer safer, more innovative, and more sustainable solutions, positioning itself as the best partner in the manufacture of more efficient and environmentally friendly mobility. More information can be found in the Sustainability Report.

In conclusion, Teknia supplies exterior vehicle parts to major companies through competitive and efficient manufacturing processes. The combination of innovative technologies, highly qualified personnel, and advanced capabilities for producing high-quality components for the automotive industry ensures that the company is well positioned to continue growing as the market evolves toward new mobility.

Plants specialised in exteriors

Ampuero

Manresa

Nashville

For any questions, send us an email

Get to know our technologies